Why This Checklist Could Save You Tens of Thousands

A boat pre purchase inspection checklist is your first line of defense against making a six-figure mistake. Before you hand over any money or sign any agreements, you need a systematic method to evaluate the vessel’s true condition—not just the seller’s presentation.

Essential components of a boat pre purchase inspection checklist:

- Hull and Deck Structural Integrity – Blisters, soft spots, stress cracks, thru-hulls, keel and rudder condition

- Engine and Mechanical Systems – Fluid condition, hoses, belts, exhaust, steering, propeller, bilge pumps

- Electrical and Plumbing Systems – Battery condition, wiring organization, breaker panel, navigation lights, head and sanitation

- Interior Condition – Signs of water intrusion, mold, upholstery condition, galley functionality

- Sea Trial Performance – Engine behavior under load, steering response, system functionality underway

- Documentation Review – Hull Identification Number (HIN), title verification, maintenance records, previous surveys

Most insurance companies require a professional marine survey before coverage begins. Professional surveys typically cost north of $500, but they can uncover issues that would cost tens of thousands to repair. Your personal checklist helps you decide whether a boat is even worth the cost of that professional evaluation.

As Andrew Gallant, a SAMS® Surveyor Associate at Marine Surveys of North Carolina, I’ve conducted hundreds of pre-purchase surveys across coastal and inland North Carolina waterways, and I’ve seen how a methodical boat pre purchase inspection checklist protects buyers from costly oversights. This guide distills that professional inspection methodology into a practical framework you can apply before you commit to a full survey.

Why a Pre-Purchase Inspection Is a Non-Negotiable Step

Purchasing a boat, especially a pre-owned vessel, represents a significant investment. A pre-purchase inspection is the critical barrier between a sound investment and a costly liability. It provides an objective assessment of the vessel’s condition, moving beyond the seller’s presentation to uncover potential issues that could impact safety, insurability, and value. This methodical approach protects your financial interests and ensures you are making a fully informed decision.

We understand the excitement of finding your ideal boat, whether it’s for cruising the Intercoastal Waterway in Wilmington, exploring the Outer Banks, or enjoying the serene waters of Lake Norman. However, that excitement must be tempered with due diligence. Hidden issues, such as hull osmosis, deck core rot, or engine problems, can quickly turn a dream into a financial burden. The ongoing costs of owning a sailboat, for instance, can easily amount to 5-10% of the boat’s value annually, and unexpected repairs can inflate this significantly. Our goal is to minimize those unwelcome surprises.

A comprehensive inspection helps us determine if a boat is worth its asking price, if it is safe for operation, and if it meets the necessary standards for insurance and potential financing. The cost for these inspections, including both the preliminary self-inspection and a professional marine survey, are typically paid for by the buyer. While a professional survey is often required and is the most important step in the buying process, your initial checklist empowers you to make an informed decision about proceeding with that professional assessment.

Preparing for Your Inspection: Documentation and Tools

Before you step aboard, proper preparation is key to an efficient and thorough evaluation. This initial phase sets the tone for a serious inspection and ensures we have the necessary context and equipment to assess the vessel accurately.

Begin by requesting all available documentation from the seller. This includes the vessel’s title and registration, which we will cross-reference with the Hull Identification Number (HIN) found on the boat. The HIN is a unique, 12-character identifier, and verifying its presence and accuracy is a legal requirement for boats manufactured after 1972 in the U.S. Altering or removing a HIN is a federal crime, so any discrepancies are a major red flag.

We also want to review maintenance logs, service records, and any previous survey reports. These documents provide a historical overview of the boat’s care, potential issues, and past repairs. A well-documented history often indicates a conscientious owner.

For our physical inspection, we bring essential tools. A powerful flashlight is crucial for illuminating dark bilges, lockers, and engine compartments. A small tapping hammer (4 oz.) is invaluable for sounding the hull and deck to detect soft spots, which can indicate water intrusion or delamination. While a moisture meter is best left to professional surveyors, understanding its purpose can help us identify areas of concern. A camera for photo documentation and a notebook for detailed observations are indispensable for creating a comprehensive record of our findings.

To conduct a thorough preliminary inspection yourself, we recommend bringing the following essential tools:

- Powerful flashlight

- Small tapping hammer (4 oz. or a plastic mallet)

- Camera (smartphone is usually sufficient)

- Notebook and pen

- Small mirror for hard-to-reach areas

- Pry bar or screwdriver (for opening access panels, with permission)

- Gloves

- Clean rags

- Binoculars (for inspecting rigging from a distance)

If you have questions about specific tools or aspects of preparing for your inspection, we encourage you to review our FAQ.

Your Comprehensive Boat Pre Purchase Inspection Checklist

This checklist is broken down into the vessel’s core areas. Approach each section methodically, documenting your findings with notes and photographs. This is a preliminary evaluation to identify red flags before committing to a professional survey. We recommend using a scoring system from 1 to 5 for each item, where 1 is “poor” and 5 is “excellent.” If your evaluation yields more than 10 scores of 2 or under, it might be wise to keep shopping. This objective assessment helps us compare vessels and make data-driven decisions.

The Hull and Deck: Structural Integrity

The hull and deck form the foundation of the vessel. Issues here can be the most expensive and difficult to remediate, often involving extensive fiberglass work or core replacement. Pay close attention to signs of stress, water intrusion, or impact.

- Hull Condition (Below Waterline): When the boat is hauled out, inspect for blisters, which can indicate osmosis. A few isolated blisters may be manageable, but widespread blistering requires professional assessment. Look for stress cracks, especially around the keel-hull joint, thru-hulls, and areas of high stress. Check the bottom paint condition; excessive layers can hide underlying problems. We tap the hull with our hammer, listening for solid sounds. Dull thuds suggest soft or hollow spots, indicative of water intrusion into a cored hull.

- Thru-hulls and Seacocks: Crucially, check all thru-hulls. Ensure they are made of bronze or another appropriate marine-grade material; plastic thru-hulls below the waterline can be an insurance issue. Operate each seacock to confirm it opens and closes smoothly. Seized seacocks are a common and dangerous issue.

- Keel and Rudder Inspection: For sailboats, inspect the keel for signs of impact or movement. Check the rudder for any play in its bearings; it should have minimal movement. Examine the propeller and shaft for bends, nicks, or corrosion.

- Deck Condition: Walk and tap the entire deck, listening for soft spots. These indicate delamination or core rot, a common and costly repair. Inspect stanchions and railings for security and signs of leaks where they meet the deck. The hull-to-deck joint should be clean and sealed, without cracks or separation. Examine all hardware and fittings for secure mounting, corrosion, or signs of stress.

- Gelcoat and Finish: Look for spider cracks, especially around fittings or high-stress areas. While minor spider cracks can be cosmetic, larger ones may indicate structural issues. Check for repairs, signs of filler, or discolored areas that might hint at previous damage.

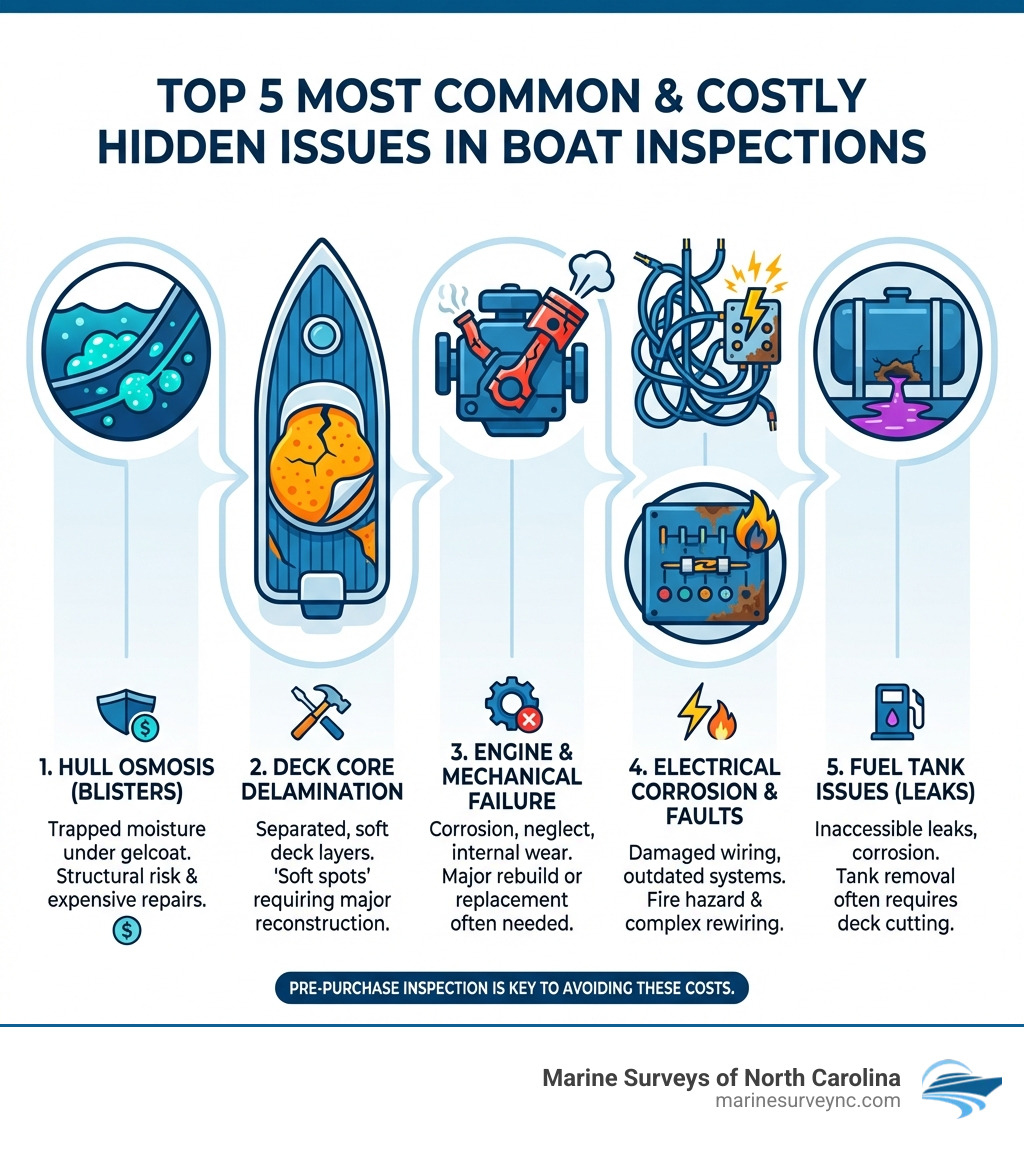

We often find that structural issues, though hidden, are among the most costly. For a deeper dive into what we commonly uncover in our North Carolina surveys, review our insights on the Top 7 Hidden Issues Found in Pre-Purchase Surveys on NC Coast.

Engine and Mechanical Systems: The Heart of the Vessel

The engine is often the most expensive component of any boat. Mechanical failures are a leading cause of on-water incidents and significant expense. A careful review of the engine and supporting systems is critical.

- Engine Appearance: A clean engine bay often indicates an owner who prioritizes maintenance. Look for signs of leaks (oil, fuel, coolant) and corrosion. Check the engine block, exhaust manifolds, and mounts.

- Fluid Levels and Condition: Inspect engine oil (look for milky residue, which indicates water), transmission fluid, and coolant levels. Note their color and clarity. Check for heat exchanger zincs on freshwater-cooled engines.

- Hoses and Belts: Flex hoses to check for cracks, stiffness, or deterioration. Belts should be tight and free from fraying.

- Exhaust System: Inspect the exhaust for leaks, corrosion, or excessive soot.

- Steering System: Check for smooth operation from lock to lock. For hydraulic systems, look for leaks. For cable systems, inspect cables and pulleys.

- Propeller and Shaft: Examine the propeller for damage (bends, nicks). Check the propeller shaft for trueness and the cutlass bearing for excessive play.

- Bilge Pumps: Locate all bilge pumps (manual and automatic). Ensure they are clean, properly mounted, and wired. Test their operation.

- Fuel Tanks: Inspect the tanks for corrosion, especially on metal tanks. Check fuel lines and filters for leaks or deterioration.

- Engine Hours: While not always perfectly accurate if gauge clusters have been replaced, engine hours provide a general indication of use. We also cross-reference maintenance records for consistency.

If the vessel includes a trailer, it requires its own inspection.

- Trailer Inspection (if applicable):

- Brakes: Test trailer brakes for functionality.

- Tires: Check tire condition, tread depth, and inflation. Look for dry rot or cracking.

- Frame Rust: Inspect the trailer frame for rust, especially at welds and connection points.

- Lights: Verify all trailer lights are operational.

- Bunks/Rollers: Ensure bunks or rollers are in good condition and properly support the hull.

For a deeper understanding of what we look for in marine engines, our Engine Systems Review offers valuable insights. We also encourage you to download a printable Boat Evaluation Checklist from BoatUS for your inspection.

Electrical, Plumbing, and Interior Systems

Onboard systems contribute significantly to the safety and comfort of the vessel. Faulty wiring or plumbing can lead to fire hazards, water damage, or system failures at inconvenient times, sometimes far from the marinas of Beaufort or Morehead City.

- Battery Condition: Inspect batteries for corrosion at terminals, secure mounting, and overall physical condition. Note their age and type.

- Wiring Organization: Open electrical panels and access points. Look for neat, organized wiring. Messy, haphazard wiring or a mixture of different fuse types can indicate amateur repairs and potential hazards.

- Breaker Panel: Ensure the breaker panel is clearly labeled and all breakers function.

- Navigation Lights: Test all navigation lights (bow, stern, masthead) for proper operation.

- Electronics Functionality: Test all onboard electronics, including GPS, VHF radio, depth sounder, radar, and other communication equipment. Ensure they power on and appear functional.

- Plumbing Leaks: Inspect all plumbing lines, especially in the bilge and under sinks, for leaks, drips, or signs of previous water damage.

- Head and Sanitation System: Test the marine head. Check the holding tank, hoses, and macerator pump (if present) for leaks, odors, or blockages.

- Freshwater System: Test freshwater pumps, faucets, and showers. Check water tanks for condition and signs of contamination.

- Interior Condition: Look for signs of leaks or water intrusion, such as stains on overheads, bulkheads, or cabinetry. Check upholstery for tears, wear, or mold/mildew. A strong, musty smell often indicates hidden moisture or rot.

- Galley Appliances: Test all galley appliances (stove, refrigerator, microwave) for functionality.

The Sea Trial: Assessing Performance Under Load

A vessel can appear perfect at the dock but reveal significant issues underway. The sea trial is your only opportunity to assess the boat’s performance, handling, and systems under real-world conditions. It’s a critical step that no preliminary checklist can fully replicate.

During the sea trial, we focus on several key areas:

- Engine Performance: Observe the engine’s start-up. Does it start easily? Does it produce excessive smoke? Once underway, listen for unusual noises or vibrations. Check the engine temperature and oil pressure gauges. We test acceleration, cruising speed, and reverse thrust.

- Vibration and Noise: Pay close attention to any excessive vibration or unusual noises from the engine, transmission, or running gear. This can indicate alignment issues, worn components, or propeller damage.

- Steering Response: Test the steering system at various speeds. It should respond smoothly and predictably from lock to lock.

- System Checks Under Load: Operate other onboard systems while underway. Does the electrical system handle the load? Are there any unexpected alarms or failures?

- Electronics Testing: Verify that navigation electronics (GPS, chartplotter, radar) function correctly while the boat is moving.

- Sail Handling (for sailboats): If inspecting a sailboat, raise and lower all sails. Observe their condition under load, checking for tears, chafe, or excessive stretch. Test winches and clutches.

- Rigging Inspection Under Load: While sailing, observe the standing and running rigging. Look for any signs of undue stress, creaking, or movement.

A sea trial on the waters off North Carolina, whether in the sounds or the open ocean, provides invaluable insights into the vessel’s true operational health.

From Checklist to Negotiation: Identifying Red Flags and Leverage

Your inspection findings are not just about identifying problems; they are a powerful tool for negotiation and decision-making. Understanding what constitutes a major red flag versus a minor, correctable issue is key.

Common Red Flags and Deal-Breakers:

- Structural Damage: Extensive hull damage, widespread core rot in the deck, or significant issues with the keel-hull joint are often deal-breakers due to the high cost and complexity of repair.

- Major Engine Issues: A failing engine, evidence of saltwater intrusion into the engine, or a non-functional transmission can lead to tens of thousands in repair or replacement costs.

- Seized Seacocks: While seemingly minor, seized seacocks pose a serious safety hazard and can be surprisingly difficult and costly to replace, especially if they require hauling the boat.

- Extensive Water Intrusion/Mold: Signs of widespread leaks, persistent moisture, or significant mold growth indicate long-term neglect and can lead to structural rot, electrical issues, and health concerns.

- Outdated or Compromised Electrical Systems: Messy, corroded, or non-compliant electrical wiring can be a fire hazard and an expensive professional rewire.

Using Findings for Negotiation:

Any issues we identify during our preliminary inspection can be used to negotiate the price. We aim to estimate the repair costs for these items. For instance, if a boat has damaged decals, a torn waterline cover, or a missing bow filler cushion, these seemingly small items can collectively translate into hundreds or even thousands of dollars in credits or price reductions.

For larger issues, such as a need for significant engine work or extensive deck repair, these findings provide strong leverage for a substantial price adjustment. Our insights from a damage survey can be particularly useful in this regard. Understanding How to Use a Damage Survey to Identify Necessary Repairs and Save Money can be a powerful tool in your negotiation process. Everything is negotiable, and a thorough inspection provides the data to back up your requests.

Specifics for Your Boat Pre Purchase Inspection Checklist: Sail vs. Power

While the core principles of inspection remain consistent, different boat types have unique components that require specific attention during your inspection.

Powerboat Specifics:

- Inboard vs. Outboard Checks: For outboards, check the lower unit for impact damage, propeller condition, and ensure the engine lifts and trims smoothly. For inboards, focus on engine mounts, shaft alignment, and transmission.

- Sterndrive Components: Inspect bellows for cracks, check trim/tilt mechanisms, and ensure the lower unit oil is free of water.

- Engine Hours: Powerboats, particularly those used for watersports, often accumulate engine hours quickly. Verify hours against maintenance records and consider a mechanical inspection.

Sailboat Specifics:

- Standing Rigging: This includes shrouds, stays, and turnbuckles. Look for broken strands, corrosion, bent fittings, or signs of stress. Standing rigging typically has a lifespan and may need replacement every 10-15 years.

- Running Rigging: Inspect all lines (halyards, sheets, control lines) for chafe, UV damage, or stiffness.

- Sails and Mast Condition: Examine sails for tears, patches, UV degradation, or stretched seams. Inspect the mast and boom for corrosion, bends, or damage. Check mast step connections (above and below deck) for leaks or movement.

- Chainplates: These are critical structural components where the rigging attaches to the hull. Look for corrosion, stress cracks in the surrounding deck or hull, or signs of water intrusion.

Whether you are looking at a sleek powerboat for coastal cruising or a robust sailboat for adventures beyond New Bern, tailoring your checklist ensures a focused and effective preliminary inspection.

When Your Checklist Isn’t Enough: The Role of a Professional Marine Survey

A personal checklist is an invaluable screening tool. It helps us identify initial red flags and decide if a vessel warrants further investigation. However, it is not a substitute for a professional marine survey.

Here’s why a professional marine survey is critical:

- Insurance and Financing Requirements: Most insurance companies and financial institutions in North Carolina and beyond will require a Condition and Valuation (C&V) survey performed by an accredited marine surveyor before they will bind coverage or approve a loan.

- Surveyor’s Expertise and Tools: Our SAMS SA certified marine surveyors possess specialized knowledge, experience, and diagnostic tools (like advanced moisture meters, thermal imaging, and engine diagnostic software) that go far beyond a buyer’s visual inspection. We can detect delamination, hidden corrosion, and mechanical issues that are invisible to the untrained eye.

- Uncovering Hidden Defects: We regularly find hidden issues that a preliminary inspection simply cannot uncover. These can range from structural compromises to complex electrical faults or engine problems that require professional diagnostic equipment.

- Legal and Financial Protection: A comprehensive survey report provides an unbiased, detailed assessment that protects you legally and financially. It serves as a benchmark for the vessel’s condition at the time of purchase and can be invaluable if disputes arise later.

- SAMS SA Certification: As SAMS SA certified marine surveyors, we adhere to rigorous professional standards and ethical guidelines, ensuring you receive a thorough and objective report.

Your checklist helps you make a “good buy” or “good bye” decision quickly. But once you’ve decided a boat has potential, a professional survey is the next, non-negotiable step. For a detailed understanding of the differences and benefits, we encourage you to review our insights on Preliminary vs Full Marine Survey: Making the Right Choice.

Protecting Your Investment in North Carolina

The journey to boat ownership in North Carolina, from the busy marinas of Morehead City to the quiet coves of Lake Norman, should be an exciting one, not fraught with anxiety. A thorough inspection process, beginning with a detailed boat pre purchase inspection checklist and culminating in a professional survey, is the most effective way to protect your investment.

This comprehensive approach provides the clarity and confidence needed to proceed with a purchase or walk away from a potential problem. Our findings ensure the vessel is safe, insurable, and valued appropriately, aligning with both your personal enjoyment and long-term financial goals. We are dedicated to providing the expertise necessary to deliver this peace of mind.

To ensure a comprehensive evaluation of your potential investment, review our pre-purchase marine survey process.